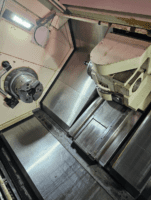

2012 Okuma MULTUS B400II-W CNC Turn-Mill Center w/ Fanuc Robot

2012 Okuma MULTUS B400II-W CNC Turn-Mill Center w/ Fanuc Robot

Low Hours – Fully Equipped – Under Power

Price: $249,000 (Includes machine, robot, tooling, and accessories)

Location: Currently under power – walk-around video available

Availability: Immediate

Rigging: Rigger required – freight not included

Overview

For sale is a 2012 Okuma MULTUS B400II-W CNC multitasking turn-mill center equipped with a Fanuc robot and an extensive tooling package. This machine has only 230 cutting hours, is in excellent condition, and remains under power for inspection.

The MULTUS B400II-W is a highly capable production platform featuring a full B-axis universal head, sub-spindle, Y-axis, live tooling, and 80-station Capto C6 ATC, making it ideal for complex, complete-in-one machining.

Key Highlights

-

Only 230 cutting hours

-

Fanuc robot included

-

Abundant tooling included

-

Full B-Axis universal head

-

Main & sub-spindle configuration

-

Y-axis and live tooling

-

80-station Capto C6 ATC

-

1,000 PSI coolant through spindle

-

Ballbar test results available (all axes and spindle tested)

-

Walk-around video available

CNC Control

-

Okuma OSP-P300S CNC Control

-

Hi-Cut Pro

-

Hi-G Control

-

ADMAC 3D Virtual Monitor

Machining Specifications (Buyer to verify)

-

Max Swing Over Saddle: 27.95″

-

Max Machining Diameter: 27.95″

-

Max Distance Between Spindles: 59.06″

-

X-Axis Travel: 27.17″

-

Z-Axis Travel: 60.83″

-

Y-Axis Travel: 9.02″

-

B-Axis Rotation (Universal Head): 225°

-

C-Axis Resolution: 0.001°

-

Spindle Bore: 4.33″

-

Spindle Nose: A2-11

-

Main Spindle Horsepower: 40 HP

-

Spindle Speed Range: 38 – 3,800 RPM

Spindles & Workholding

-

Main Spindle: 12″ Kitagawa B-12 / B-15 3-Jaw Power Chuck

-

Sub-Spindle: 12″ Kitagawa B-12 / B-15 3-Jaw Power Chuck

Tooling & Milling

-

ATC Capacity: 80-Station Capto C6

-

Live Tooling Horsepower: 14 HP

-

Live Tooling Speed Range: 90 – 6,000 RPM

-

H1 Turret

-

Lathe tool indexing

-

Two (2) tooling carts with tooling included

Coolant & Accessories

-

Chip Blaster system

-

1,000 PSI coolant through spindle

-

Elevated chip conveyor

-

Touch setter

-

Touch sensor

-

Spindle chiller

-

Oil cooler

Shipping Components & Dimensions

(5 major components)

-

Machine: 193″ L × 9′ W × 9′ H

-

Chip Conveyor: 200″ L × 49-1/2″ W × 6′ H

-

Chip Blaster: 25-1/2″ L × 54″ W × 80″ H

-

Spindle Chiller: 40-1/2″ L × 14-1/4″ W × 39″ H

-

Oil Cooler: 17-3/4″ L × 17″ W × 39″ H

Total Machine Weight: Approx. 34,000 lbs

Additional Information

-

Machine is currently under power

-

Walk-around video available upon request

-

Ballbar test results available for all axis and spindle

-

Specifications subject to buyer verification

Price: $249,000 – Complete Package

Includes machine, Fanuc robot, tooling, and accessories.

📞 Inquiries : Contact for inspection, video, or additional details. 1-888-884-2447